How to build a convenient greenhouse from a profile with your own hands

Content

Is it worth building a greenhouse from a profile?

The profile frame for a greenhouse has a number of important advantages:

- A greenhouse built with your own hands from a profile can be of any size and shape.

- This type of frame is lighter than metal or wood. A small, profiled greenhouse with a lightweight covering can be moved from one place to another without disassembling.

- The greenhouse frame made of galvanized profile does not rust due to high air humidity and direct water ingress, and is resistant to heavy snowfalls and strong winds.

Video: "DIY Greenhouse from Profiles and Polycarbonate"

This video will show you how to build a greenhouse yourself using profiles and polycarbonate.

What profiles exist?

Several types of profiles are used to manufacture greenhouses:

- Steel pipe with a square or rectangular cross-section. The most durable material, suitable for large structures with heavy coatings. It's best to purchase pipe that's galvanized by the manufacturer—this significantly increases its corrosion resistance. For a substantial, long-term greenhouse, galvanized profiles are especially important—they're resistant to rain, snow, and meltwater. You can also galvanize the pipe yourself using galvanic or cold galvanizing methods.

- U-shaped or U-shaped profiles. They may differ in overall cross-section width and wall thickness. They can be made of galvanized steel, anodized aluminum, or drywall with corrugations for added strength, as well as other materials.

- A V-shaped metal profile with a flared bottom. Designed specifically for greenhouse construction. Inexpensive and lightweight, but not the most durable option.

- U-shaped, square, and other PVC profiles. Less durable than metal, but more flexible and less expensive.

- Profiles designed for plasterboard coverings. Although this material is rarely used directly for greenhouses, these profiles are inexpensive, easy to assemble with screws and fasteners, and easy to cut with metal shears. Greenhouses made from plasterboard profiles are quite practical and reliable.

Variety of shapes and designs

Before building a greenhouse, you should first decide on its shape.

One of the most practical options is a greenhouse with a gable roof. Snow slides off it quickly and provides maximum usable space. However, such a greenhouse requires a large expenditure of materials and labor-intensive roof sheathing.

A lean-to greenhouse is similar to the previous option, but its roof slopes to one side. This type of structure is typically an extension to a house or outbuilding.

From houses of this kind it is possible to build a real greenhouse complex.

Arched greenhouses are popular due to their simple design. They consist of a series of arches connected by horizontal braces. They can be easily extended as needed. They are wind-resistant and easy to assemble and dismantle. However, some of the space inside such a greenhouse is difficult to use. They require flexible profiles or tools to bend them into arches. Snow slides off more easily, and it often has to be cleared by hand.

An A-frame greenhouse is easy to construct, but it offers very little usable space inside. Furthermore, its cladding is quite labor-intensive.

There are other designs: spherical, Mittlider, tent-shaped, etc. However, their construction is labor-intensive and requires complex calculations, so they are more suitable for experienced gardeners.

To ensure that the structure is resistant to snow and wind loads, meets the necessary agricultural conditions, and fits within the budget, its design must be carefully thought out beforehand.

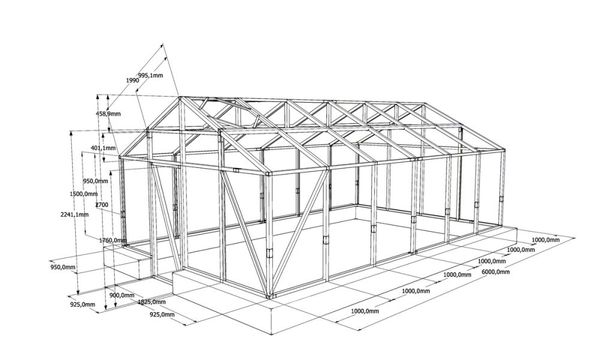

The drawing can be created either on paper or in one of the special programs (for example, Google SketchUp).

First, determine which shape will best suit your needs. Then, choose the dimensions of the future structure, taking into account the characteristics of the covering material. For example, cellular polycarbonate sheets have a standard size of 6 x 2.1 m.

Please note that the cladding elements can be fastened either by overlapping or using connecting profiles.

A typical residential greenhouse is typically 2–3 m wide and up to 10 m long. The optimal height for an arched or A-shaped structure is approximately 1.9–2.1 m. For a gable-roofed greenhouse, it can be even higher. The slope angle for the slopes should be 25–30°.

Consider the location of the doorway and windows.

Finally, draw a general frame that includes all the necessary elements, and calculate the amount of frame and covering material required, as well as fasteners, with a 10-15% reserve (for greater convenience, you can use a free construction calculator program).

We are making the foundation

The greenhouse location should be sunny and sheltered from northerly winds, with fertile soil and a minimal slope. If the greenhouse is intended for a specific crop, its growing requirements should be taken into account—for example, zucchini prefers neutral soil.

The foundation for a profile greenhouse can be:

- tape;

- brick;

- stone;

- pile (suitable for uneven terrain or soil prone to waterlogging);

- wooden.

Since the greenhouse's profile frame is relatively lightweight, many gardeners recommend the latter option. Durable and rot-resistant larch is best.

Dig a trench the depth of a shovel blade. After compacting the bottom, add a layer of gravel or sand (25–30% of the total depth).

After cutting the beams around the perimeter of the greenhouse, treat them with an antiseptic: used motor oil, bitumen, or copper sulfate.

Using screws or brackets, assemble the beams into a rectangle and lay it in the trench. To ensure horizontal alignment, you can add sand or place small boards underneath.

Drill through holes in the corners of the foundation and drive reinforcement rods up to 1 m long into the ground through them.

Seal the gaps between the beams and the ground with sand or soil. You can cover the tree with roofing felt.

Selecting the material and assembling the frame

The frame material is selected , based on the dimensions of the future structure and covering. For perennial and especially winter greenhouses, galvanized steel profiles are preferred. For lightweight portable structures, plasterboard or V-shaped profiles can be used.

, based on the dimensions of the future structure and covering. For perennial and especially winter greenhouses, galvanized steel profiles are preferred. For lightweight portable structures, plasterboard or V-shaped profiles can be used.

An arched structure can be welded or prefabricated. The elements can be made by hand using a pipe bender. Good greenhouse arches can also be made from profiled tubing: to do this, cut a 2/3-width notch on one side of the profiled tubing with a grinder, then bend it and weld the seams.

Let's look at a step-by-step plan for creating a homemade arched case.

- If necessary, drill holes in the arch elements according to the diagram and connect them into a semicircular structure.

- To strengthen the arches, attach crossbars and braces to them.

- Install the vertical posts, diagonal crossbars, and door frame. You can use triangle plates and corners for this.

- Secure the side and top braces to the gable, then attach the intermediate arches to them.

- At the end of the arch, assemble and install another blind pediment.

- Using anchor bolts or corners and screws, secure the finished frame to the foundation.

How and what to use to cover a greenhouse

As an example, let's look at instructions for covering a greenhouse with polycarbonate, one of the most popular materials.

- If necessary, cut the sheet and remove the protective film. Seal the top edges with sealing film and the bottom edges with perforated tape.

- Place the sheet against the gable and secure with thermal washers or roofing screws.

- Cut out a hole for the door. Trim off any excess.

- Strengthen the opposite gable.

- Place the sheets on the walls of the greenhouse and secure them with screws.

Please note: polycarbonate is always laid with the stabilizing coating facing outwards.

For lightweight greenhouses, film is often used as a covering. It is pressed against the frame with slats, then secured with screws. This should be done on a cloudy day or in the evening to prevent glare from obscuring sagging areas.