Types of greenhouse bread bins and assembly features

Content

Design Features

The design gets its name from a kitchen appliance with a similar operating principle: a bread bin. This type of structure consists of a foundation and two movable parts attached to it, which are hinged. Greenhouses that open only on one side are common among farmers, but double-sided models also exist.

The ability to fully open either side of the structure, as well as the adjustable height of the sashes, allows for the creation of the necessary microclimate for germination and subsequent crop growth. Furthermore, a breadbox greenhouse requires no additional heating systems. A method known as "warm beds" is often used. This method involves the release of energy through the decomposition of organic matter.

To create the frame, either metal profile pipes or hollow polypropylene pipes with strong walls are used. Polycarbonate sheets or film are commonly used for cladding, which can be easily replaced even if damaged. Furthermore, the former, combined with the classic arched shape, allows the structure to remain on site during the winter.

Video: Making a DIY Greenhouse Breadbox

This video will show you how to make your own breadbox greenhouse.

Advantages and disadvantages

Since everything created by man and nature has a purpose, "bread bins" can't boast universality. Therefore, it's only natural for this type of greenhouse to have both advantages and disadvantages. Gardeners note the following advantages:

- availability of drawings, materials and ease of DIY production;

- ease of assembly of component parts when purchasing a finished product;

- long service life of the greenhouse due to the possibility of replacing individual parts of the cladding;

- Suitable for growing many crops, except for vigorous and climbing ones;

- has a low weight, which facilitates dismantling and moving the structure;

- The creation or acquisition of a ready-made model does not require large financial expenses.

You should also not ignore the points that can cause problems when using the "bread bin". Among them:

- the low weight of the greenhouse in combination with the open position of the sashes can cause the structure to shift in windy weather conditions;

- hinges require regular inspection;

- in some cases it becomes necessary to install supports to prevent the moving parts from closing spontaneously;

- The small dimensions typical of greenhouses of this type do not allow for the cultivation of tall crops.

Main varieties

Among the many materials used for exterior cladding, polycarbonate breadbox greenhouses are a leader. This type of cladding is popular not only among homeowners but also in commercial agricultural settings. However, structures belonging to the "breadbox" type are intended for private use only, regardless of the construction type of individual varieties.

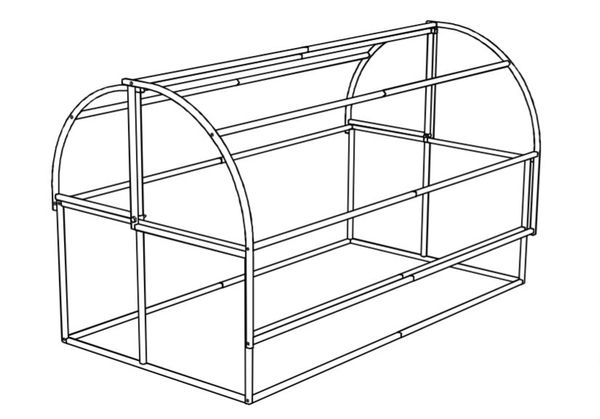

Arched

The classic version, the base of which consists of several identical, parallel arches, fixed to the foundation or dug into the ground. Access to the seedlings can be achieved by installing a movable element or, even more simply, by lifting or removing part of the covering.

"Butterfly"

What makes this model unique is that instead of the greenhouse halves moving relative to each other, it has doors that, when open, resemble the wings of the insect of the same name. This design is convenient, as it allows maximum access to the plants, but adjusting and securing the doors requires supports.

Ground or French

A structure of this type can have any microclimate control mechanism. In fact, it can be any greenhouse, the distinctive feature of which is its above-ground location. This design is convenient for frequent relocation or dismantling for the winter.

In-depth

The principle of this "breadbox" model is that the visible above-ground element is the roof, providing light to the seedlings. The rest of the greenhouse is sunken into the ground to improve heat production and retention.

Assembling a ready-made greenhouse-breadbox

Due to their small size, you can find pre-assembled greenhouses for sale, practically ready for use. However, models that require a little effort are also widely available. If you follow the instructions, a breadbox greenhouse, assembled and installed by yourself in your garden, can even become a beautiful addition.

Production models may have various additions, such as legs, the presence or absence of a bottom frame, and other elements. However, in general, assembly involves the following process:

- connection of horizontal ties;

- placing the elements in the form of a semi-arc next to each other and then covering them with polycarbonate using self-tapping screws;

- cutting the sheet to the shape of the frame elements and repeating the procedure for the remaining ones, including the basement ones;

- connecting the side basement parts with pre-prepared horizontal ties, and covering the gaps of the resulting structure with cladding material;

- connection and sheathing of parts that are parts of the sashes;

- installation on the base of a smaller sash;

- fastening a larger, movable sash to a hinge bolt;

- equipping the structure with plugs and handles.

After completing all assembly steps according to the drawings, it's necessary to check the functionality of all moving and locking parts. Furthermore, for proper operation of the greenhouse, a foundation is required, which can be made of heavy wooden beams or brick. The key is to ensure that the perimeter of the "breadbox" matches that of the foundation.

How to make it yourself

Craftsmen who want to put maximum effort into creating their own creation will find the Fedorov greenhouse drawing useful. The data is freely available and will be extremely helpful in calculating the dimensions and materials required.

The frame can be made of wood, but its components are bulky and fragile. Plastic pipes are also an option, but metal profile elements are the best option, as they are lightweight, strong, and relatively durable.

To work you will need:

- rectangular metal pipes 15 mm thick and 20 mm wide on each side;

- pipe bender;

- welding machine;

- hinges;

- connecting parts in the form of bolts and screws;

- several sheets of polycarbonate;

- dye;

- minimal skills in working with the above-mentioned equipment.

The metal "skeleton" must be painted—this serves as a kind of protection for the material. Assembly is virtually identical to that of prefabricated components. Additionally, some work will be required to form the arched parts and weld them. With careful attention to detail and careful reading of the drawings, the Fedorov greenhouse (also known as the "breadbox") will last for at least ten seasons.