Advantages and disadvantages of a solar bio-vegetarium

Content

Pros and cons of the design

Ivanov's solar vegetarium was first developed in the middle of the last century. But at that time, the Kyiv physics teacher's work was not fully appreciated. Scandinavian agricultural engineers used his experience, refined the technology, automated some processes, and created a modern biofactory.

Experienced gardeners choose vegetariums over the vast number of other modern arched and gable-roofed options because new-generation greenhouses offer numerous useful and advantageous benefits:

- operate on energy-saving principles, significantly reducing growing costs in any season;

- They grow only natural and healthy organic products, as the main fertilizer is organic matter;

- the development and ripening time of popular vegetable crops (zucchini, radishes, cucumbers, early cabbage) is accelerated by 1 month;

- At a temperature of 32 °C, tomatoes produce 3 times more yield, and eggplants – 4 times more;

- 44 kg of cucumbers and tomatoes can be harvested from 1 sq. m;

- The cost of producing a kilogram of produce is significantly lower than in Dutch greenhouses.

Greenhouses have virtually no drawbacks, although some users find the design and installation complicated. The only thing you need to do is carefully study the project and think through communications: heating, lighting, ventilation.

Video "Solar Bio-Vegetarium"

In this video, an expert will explain what a bio-vegetarium is and what makes it unique.

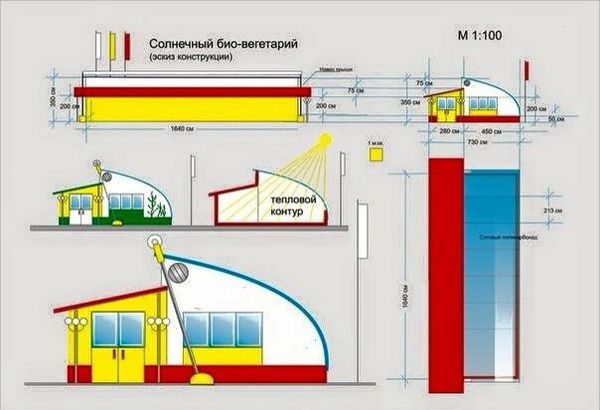

Features of a bio-vegetarium and project creation

All the secrets to creating a vegetarium are simple and accessible to those who dream of growing organic vegetables year-round. One of the main rules is to place the main wall on the north side. This will be the back of the greenhouse, so it's important to properly construct and insulate it. It can be adjacent to the house or an outbuilding. It is reinforced with boards and covered with foam. Foil insulation is also used as additional insulation.

The purpose of the main wall is to reflect light and heat, ensuring that 95% of the beneficial solar radiation reaches the plants. To achieve this, reflective materials are incorporated into the rear wall; painting it white is acceptable.

Another important factor is the slope of the surface. This can be done manually if the site is horizontal. This increases the amount of light fourfold. The basic design includes a solar greenhouse, supplemented by a seedling growing area and a bio-humus production area.

How to choose a location and install a foundation

Before you begin building a solar greenhouse yourself, you need to choose the right site. You should decide whether the new space will be attached to an existing building or house with a solid wall, or whether it will be built separately. To do this, consider the following recommendations from agricultural experts.

A slope of 10 to 30 degrees is required. This can be natural or created by hand. There should be no shading from the west or east. The most important thing to consider is that the main wall should face north, and the orientation should be south-facing only.

A good option is to attach a greenhouse to the house. Construction begins with laying the foundation. Here's a step-by-step list of steps:

- The area is being cleared.

- They apply markings.

- Dig a hole 50–100 cm deep, strictly according to the drawings. Use a hand auger or a drilling machine.

- Insert pipes with a diameter of 1.2–1.5 cm.

- Fix and fill with solution.

- A trench is dug in the ground around the perimeter according to the plan.

- They are reinforcing the foundation.

- The formwork is made from plywood - it should have 3 holes for drainage and 5 for ventilation.

- Pits are being prepared for the installation of water tanks.

The foundation is made with an insulated blind area or a strip foundation.

Selecting the material and assembling the frame

The greenhouse frame serves as a load-bearing structure and can be built by hand. Metal beams, inexpensive and durable metal, asbestos pipes, and rebar are used for construction. Profiled pipe is a good choice for this purpose.

The step-by-step instructions for creating a frame module include the following steps:

- Three assembly components are welded together. Each contains one horizontal beam and three posts.

- Grooves are made in the vertical posts to install the beam.

- Unevenness is removed with an abrasive wheel.

- A special 3-in-1 anti-corrosion paint is applied to metal elements.

- Welded structures are installed into the holes of asbestos-cement pipes.

- Fix the assembly components.

- The voids in asbestos pipes are filled with a solution.

Material and coating rules

After the frame is installed and assembled, the covering begins. The best material for this purpose is cellular polycarbonate. The wall layer should be 4 mm thick. The roof sheets should be slightly thicker – 6 mm. This results in a translucent structure.

Modern models feature a curtain system. It can save up to 40% of energy in winter by maintaining energy storage, and regulate light and temperature during hot weather. The curtain screen is made of polyester with foil elements arranged in stripes.

How to insulate and equip a vegetarium

To ensure stable indoor conditions, heating and lighting are adjusted, and irrigation and ventilation systems are installed. Automated microclimate control is essential, maintaining optimal humidity, temperature, and lighting levels.

Insulating a smart greenhouse yourself provides comfortable conditions for growing vegetables and herbs. To accumulate heat in the ground, plastic pipes at least 1 cm in diameter are installed. They are easy and convenient to work with: cut, drill, and assemble into the desired configuration.

Heating systems

When heating a bio-greenhouse during the cold season, average regional temperatures are used as a guide. The following heating device requirements are taken into account:

- safety;

- the ability to regulate heating and air movement;

- service life;

- overheating protection.

An electric heat gun is used for this. Heated air travels through pipes, warming the space. After cooling slightly, it descends along a slanted line to the soil. Fans draw it into pipes under the beds, where it transfers heat to the soil. Once completely cooled, it returns to the room. Many gardeners build their own wood-burning stove as an alternative to an electric heater.

Windows and doors

Air ventilation is essential for an optimal microclimate. Natural ventilation requires:

- doors in a blank wall;

- side transoms;

- ceiling windows.

Outside air will enter through the lower side windows. Heated air will exit through transoms near the north main wall on the greenhouse roof. These transoms are attached to the frames and equipped with clamps, allowing the opening angle to be adjusted.

Air circulation is ensured by supply and exhaust ventilation. Doors are made as strong and airtight as possible to prevent heat loss in winter.

Equipment of beds

The beds are prepared in bottomless boxes. Alternatively, a border fence can be used. The optimal width of the bed is 45–60 cm. The passageway should be the same size. Holes for the irrigation system must be drilled in the boxes. The diameter should be sufficient for the hose to pass through. It is advisable to fill the passageways with sawdust and lay tiles.

When preparing the soil, follow the instructions:

- Do not use mineral substances with heavy metal salts, pesticides, nitrates.

- Use only environmentally friendly organic matter: humus with vermiculture, manure, compost.

- Spread organic fertilizers over the bed and dig to the depth of a spade.

Organic products and organic farming are the choice of a generation striving for health and longevity. A Scandinavian-technology greenhouse, operating as a green, year-round, environmentally friendly factory, produces vegetables free of nitrates and pesticides.