Pros and cons of the Butterfly greenhouse design

Content

Greenhouse design

The Butterfly Greenhouse is a structure resembling an elongated tent—its base is rectangular and its roof is oval. The structure gets its name from its opening frames, which, when raised, resemble the spread wings of a butterfly.

This type of greenhouse is manufactured industrially from a metal-plastic frame covered with polycarbonate sheets. A homemade "Butterfly" greenhouse can be made from plastic profiles covered with film, which does not reduce the structure's stability.

In addition to its attractive shape, the Butterfly greenhouse comes in a variety of sizes and interior configurations, making it ideal for growing various crops under a single roof. The frames on each side can be connected or independent, and can open independently. This feature allows the structure to be divided into several sections (depending on the number of opening frames and your preference). Each section will maintain its own temperature and humidity levels.

It's worth discussing the frames in more detail. Factory-made greenhouses are equipped with shock absorbers as fasteners, which reduces the risk of structural failure and increases its service life. If you're planning to build your own greenhouse, you can use an automatic thermal actuator connected to a temperature sensor as a lifting mechanism. This solution will make it easier for you to care for your vegetables and also create a mechanized system to maintain an optimal microclimate inside the structure.

Video: Assembling a Butterfly Greenhouse with Your Own Hands

This video will show you how to assemble the popular "Butterfly" greenhouse yourself.

Pros and cons of the Butterfly greenhouse

The Butterfly greenhouse has a number of advantages that make it suitable for use by a wide range of consumers:

- Variability in sizes – the standard length of the greenhouse is 4 m, which allows the structure to be installed even in small areas;

- The lightweight and reliable nature of the collapsible structure allows the structure to be moved to any location on the site, eliminating the need for a foundation. Despite the lightweight materials used, the structure is quite sturdy, withstanding snow and strong gusts of wind well.

- Wide ventilation options – the Butterfly greenhouse can have all or just some of its frames raised. The former allows you to create an open garden bed, while the latter allows you to restrict fresh air access to a specific area of the greenhouse;

- greenhouse heating – the materials used quickly heat up from direct sunlight, creating an optimal microclimate for plants inside the room;

- Versatility and easy assembly are characteristics that allow even a novice gardener to set up his own greenhouse;

- Easy access to plants is provided by frames that open at a wide angle.

However, greenhouses have a number of characteristics that garden owners cite as negative. First and foremost, these are certain drawbacks related to the specific design of the structure—the opening and closing mechanism can become loose over time. Furthermore, factory-made greenhouses are prone to poor-quality paintwork, which can chip over time.

Assembly of a factory-made greenhouse

The "Butterfly" polycarbonate greenhouse comes in two varieties: prefabricated and homemade. For the latter, you'll either have to build it yourself or have it custom-made by a professional. A prefabricated greenhouse can be purchased at a hardware store.

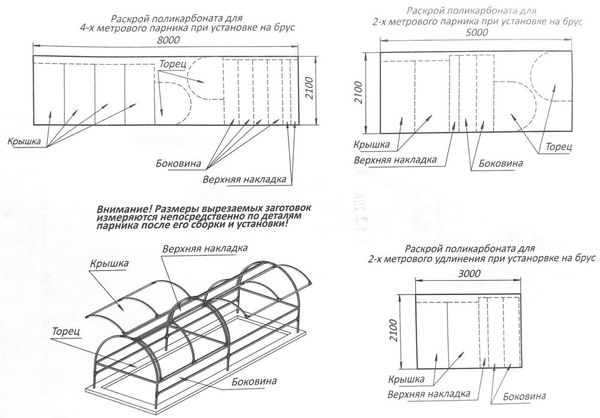

The greenhouse kit includes all the necessary tools and construction parts—metal and polycarbonate sheets, metal skeletal profiles, and screws. All you need is a set of screwdrivers, wrenches, a hammer, and a knife for cutting the polycarbonate.

First, prepare the site—the area where the future greenhouse will be located should be level and well-lit on all sides. Once you've chosen a location, decide on the foundation—this could be a strip foundation lined with bricks, boards, or any other building material you don't need.

Next, assembly of the "Butterfly" begins. First, assemble the frame and install it on the foundation. Next, attach the frames to the frame, and then cover the entire "skeleton" of the greenhouse with polycarbonate. The greenhouse is ready.

How to make it yourself

To build a butterfly greenhouse yourself, you need a blueprint and building materials that match those used in factory-made construction – metal-plastic profiles or pipes, polycarbonate or thick polyethylene film, screws, and tools (all of these items can be purchased at a hardware store or metal warehouse).

When building a homemade greenhouse, it's best to use metal-plastic or plastic pipes, which are flexible and rot-resistant. Furthermore, these pipes can be welded together if the required number of fasteners is not available.

Installing the foundation

In DIY construction, a wide variety of items can be used as foundation elements, including construction waste—bricks, concrete blocks, old slate, metal sheets, fence boards, and other items that don't add weight to the structure but make it stable.

Additionally, a trench up to 10 cm deep is dug around the perimeter of the foundation, corresponding to the area of the foundation, into which the greenhouse will later be dug. After this, the foundation is assembled: a rectangular frame that is laid within the foundation, as well as semicircular frames that are positioned across the greenhouse.

Making the frame

The frame is made from the same materials as the foundation. The pipes or profiles are connected using screws or soldered—the latter method is not recommended for prefabricated structures. Next, the frames are installed and secured to the crossbar connecting the semicircular frames. The opening mechanism—shock absorbers or thermal actuators—is attached to the window frames.

Sheathing

The final step is to sheathe the frame using polycarbonate sheets secured with screws or film secured with nails. For demountable structures, it's recommended to use smooth nails, as these fasteners are easy to remove from the profiles.

Operation and preparation for winter

After the vegetable growing season ends, the greenhouse is prepared for winter. The plastic covering is removed, washed, and stored in a shed until the next season, while the polycarbonate covering is washed. Next, the structure is inspected for damage and rust. Any defects are recommended to be repaired and the joints lubricated.