Review of manufacturers and making homemade greenhouse stoves

Content

Overview of types and manufacturers

Most wood-burning stove models are readily available, ready-made—they're produced by both large companies and numerous private workshops. Some models can be made at home.

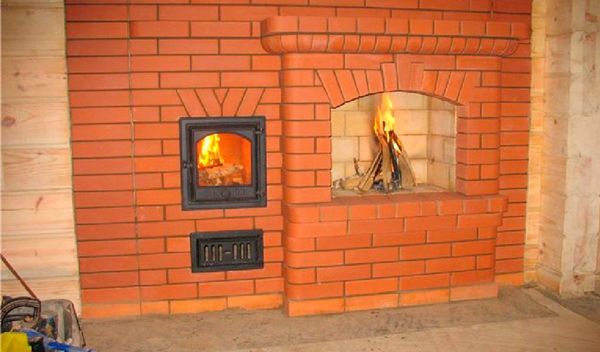

Kuznetsov's Furnace

Brick construction with two steel registers. Efficiency: 80–95%.

Inside the structure, there's a unique "hood" that connects the firebox and the lower part of the stove. This separates the gas into cold and hot, with the hot gas remaining inside, concentrating the heat, and the cold gas escaping through the chimney. This stove heats evenly and limits soot formation.

This stove can be made independently or ordered from a specialized construction company.

Rocket Stove

This greenhouse stove operates on the principle of pyrolysis: under high temperatures, solid fuel decomposes, forming a gas that burns in a separate chamber, generating a large amount of heat. This stove uses 85% less fuel than conventional designs. It gets its name from the characteristic hum it makes when starting up and which stops once operating temperature is reached.

The greenhouse is heated by a chimney running along the perimeter of the room or along it.

Vologda

A long-burning greenhouse stove: wood needs to be added every 6-10 hours, depending on the model. It operates using gas generation. Some models have a coil for heating water. Hoses can be connected to a 35- or 50-liter tank. A 35-liter tank typically heats up to +50°C to +60°C in 30-40 minutes.

Chimneys exit through the ceiling or a window. The top of the chimney should be at least 30 cm higher than the ridge to improve draft.

Please note: the first heating should be carried out outside to allow the coating to polymerize (otherwise the greenhouse will smell like burnt paint).

For better heating, it is advisable to install the model at a height of 30–60 cm from the floor.

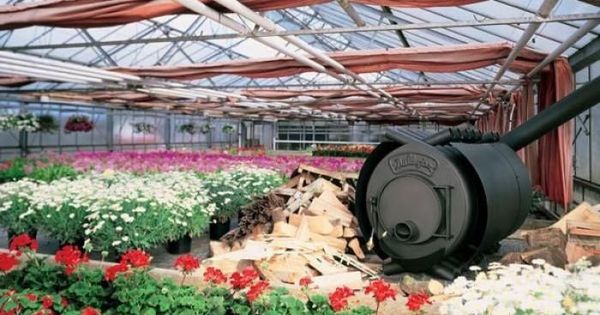

Buleryan

This design resembles a barrel lying on its side, with tubes at the top and bottom pointing in opposite directions. The lower ones are designed to draw in cold air, while the upper ones are designed to exhaust warm air. It operates on the principle of a gas generator: the wood smolders in the first chamber, and the resulting gas is completely burned in the second. This design ensures uniform heating of the room.

Efficiency: 70–75%. Fuel needs to be refilled every 6–8 hours.

This model is used less frequently for heating greenhouses due to the lack of a regulator.

Butakov's Stove

This design is somewhat reminiscent of a Buleryan stove: it operates on the principle of a gas generator, drawing in cold air from below and releasing warm air from above. It also has a convector, which provides accelerated heating of the room. The flow of cold air can be regulated, thereby setting the desired temperature.

There's a pull-out ash drawer at the bottom. The grate solves the temperature fluctuation problem.

The most famous manufacturers are: Termofor, Teplodar, Konvektika.

Slobozhanka

A relatively inexpensive and practical long-burning stove. It burns almost any fuel: wood, straw, etc. Typically, it has a top ignition system. There are three versions of this stove, differing in their air supply and movement systems.

You can easily make such a stove with your own hands.

Bubafonya

A simple design with a minimum of components. Based on pyrolysis. Runs on any solid fuel.

The cylindrical body is divided into two parts by a distinctive "pancake." The wood and combustion zone are located at the bottom. An air pipe, supplying oxygen, passes through the lid and the "pancake." The gas combustion zones are located above the pancake. A chimney extends from them.

Video: "Jet Stove for Gardens and Greenhouses"

This video will show you how to make a jet furnace for heating a greenhouse.

Types of homemade stoves

Now let's look at the types of homemade stoves for polycarbonate greenhouses.

Brick

Brick stoves are complex to build, requiring precise planning and sand-making expertise, but they provide long-lasting heating. The most common type is the "Kuznetsov stove." When installing it, it's important to follow a number of rules:

- since the brick expands when heated, the inner refractory shell must be free on all sides;

- The internal masonry of fireclay bricks is laid on the edge;

- Every two rows of bricks the bond is reinforced with wire.

It's also possible to build a stove equipped with a so-called flue: a horizontal chimney for heating the beds. The foundation should be made of iron and pipes. The firebox and chimney outlet should be located at opposite ends of the greenhouse.

From gas cylinders

You can also build a homemade stove from a used gas cylinder: its shape is ideal for the pyrolysis process, making it very efficient. It should be all-metal and capacious (at least 12 liters, ideally 50 liters). It's advisable to choose a model with a valve rather than a throttle valve—this will make it easier to regulate the combustion intensity.

Hundreds of designs have been developed to date. A particularly popular type is the waste oil furnace. The operating principle is as follows: oil is poured into the fuel compartment and ignited; air is supplied through a throttle; steam rises through the perforated walls, where the influx of fresh air intensifies the combustion process.

The afterburner has two compartments: one where the vapors burn out, and the other where the nitrogen oxides decompose into nitrogen and oxygen. Efficiency is approximately 80%. However, please note: this design is dangerous due to the risk of condensate entering the burning oil.

You can also easily make the “Bubafonya” described above from a balloon.

From barrels

You can make "Bubafonya," "Slobozhanka," and a number of other designs from an old barrel. For example, this one:

- Place 2 barrels of 200 l capacity horizontally next to each other and weld.

- At the back, make a hole for the chimney pipe with a diameter of 30–40 cm.

- Cut the front bottom in half parallel to ground level, and attach the lower half to the top half as a curtain (it should open upward). Weld a short chain to this flap, and a hook to the top of the barrel to hold the flap in place while loading firewood.

Potbelly stove

A potbelly stove can be made from almost any of the materials mentioned above: a gas cylinder, a barrel, and even a brick.

For example, to make one from a cylinder, cut off the top. Make a hole in the top for a chimney flue, and in the bottom for a perforated pipe. Make a lid from the top of the cylinder.

Manufacturing of a long-burning furnace

Gardeners often wonder how to build a simple greenhouse stove themselves. For example, let's look at how to make a "Bubafonya" from a gas cylinder:

- Cut off the top of the cylinder and secure it to the body with clamps. If necessary, weld an additional section of pipe (the total height should be 85 cm).

- Select a pancake with a diameter approximately 3 cm smaller than the inner diameter of the cylinder.

- Select a tube for the oxygen supply. Cut a hole in the center of the lid and pancake to match the diameter of the tube.

- To prevent the pancake from resting on the wood, weld six straight or curved pieces of angle iron to its back. They should extend outward from the center, directing the air flow.

- At the top of the cylinder, cut a hole for the smoke exhaust (10–15 cm), and weld a piece of pipe up to 40 cm long.

- Attach the stove to the chimney and insulate it.

To heat a greenhouse, it's best to dig such a stove slightly into the ground to ensure the roots are also warmed. The chimney should be located close to the ground.

Safety rules

The oven should be located at least 1.25 m from flammable materials and walls (polycarbonate, for example, can melt due to high temperatures). If this is not possible, careful shielding must be provided.

If a metal pipe goes through the roof, it must be double-layered, with non-combustible thermal insulation material inside.

It is important to exercise extreme caution with waste oil furnaces and to prevent condensation from entering the furnace.