Review of 4 manufacturers of reinforced greenhouse film

Content

General description and features

Reinforced polyethylene for greenhouses is a special type of covering material. It is made not only from polyethylene but also from fiberglass and polypropylene.

The material consists of three layers. Two layers are made of light-stabilizing film, and the third is a reinforcing mesh (located between the two outer layers). The inner mesh can be 0.29–0.32 mm thick and have a mesh size of approximately 1 cm.

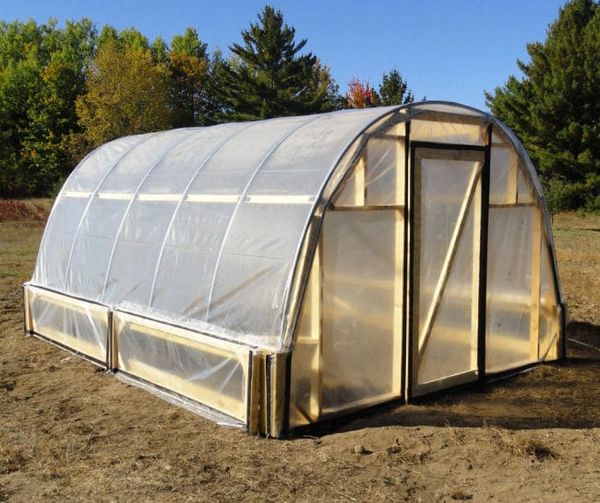

Thanks to its unique structure, reinforced film allows you to quickly cover a pre-assembled greenhouse frame. This requires minimal effort. It can also be used as a stand-alone cover, simply placed on top of the garden bed. This protection will reliably protect seedlings from frost.

The material is sold in rolls or packages of 2, 3, 4, and 6 m widths. Lengths can be 15 or 20 m. The film itself can be transparent or white. For finishing the greenhouse, it is better to use a transparent material, as it allows enough light to pass through for normal growth and development of plants.

Video: How to Attach Film to a Greenhouse

This video will show you how to properly attach the covering to the greenhouse.

Popular manufacturers

Today, various companies produce reinforced film. However, not all of them have received positive reviews. Below, we will discuss manufacturers whose products are in demand on the market.

Folinet film

Made in Korea from high-quality polyethylene with light-stabilizing properties, the reinforced layer is made of high-pressure material. The product is tear- and stretch-resistant, allowing it to effectively withstand even strong gusts of wind. If torn, the holes do not spread apart and can be repaired by hand.

Folinet products tolerate significant temperature fluctuations (from -40 to +90°C) without loss of quality. Thanks to the inclusion of special light stabilizers, the film effectively protects plants from the harmful effects of ultraviolet radiation. The product's service life is 3–6 years.

Protect film

Protect's products also feature light-stabilizing properties. This film is used not only for greenhouses but also for constructing garden ponds, silos, and other agricultural structures. It is also used to construct various plant structures. The material retains heat well while remaining completely transparent. Therefore, plants inside greenhouses receive sufficient light for development and fruiting.

Protect is highly resistant to strong gusts of wind and can also withstand significant temperature fluctuations.

The service life of this product is more than 5 years (only if all operating rules are observed).

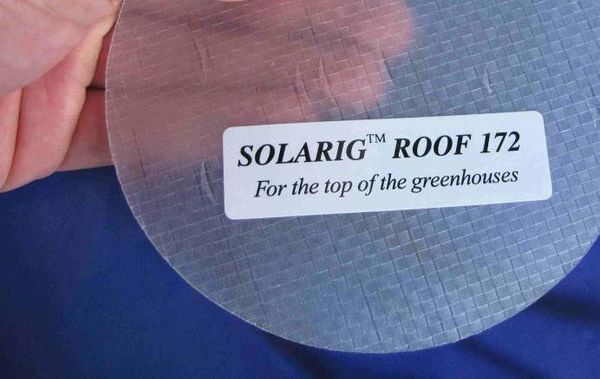

Solarig film

The manufacturer is the Israeli company PicPlast. It is made from high-quality polyethylene, which has a multilayer structure. This company's products are considered very durable.

A unique feature of Solarig is that its panels can be sewn together to form a durable cover for a greenhouse of any size and shape. The film's high strength is achieved through a special manufacturing process. The material resists tearing even under heavy snow pressure.

Vural Plastik film

This film is manufactured by the Russian company AgroKhozTorg. The material is designed for long-term use. According to the manufacturer, Vural Plastik film allows for savings of up to 15% on annual greenhouse covering compared to conventional covering materials.

The product has excellent strength in both the transverse and longitudinal directions, allowing it to withstand snow and wind loads. Three-layer extrusion technology is used in production, which involves the use of various additives that improve the material's quality.

What to consider when choosing

To ensure that reinforced greenhouse film lasts as long as possible, consider the following points when choosing it:

- Manufacturer. It's best to choose well-known and time-tested manufacturers;

- dimensions (length and width);

- Density. The denser the material, the longer it will last;

- color. You need to choose transparent films;

- The material used for production. This could be polyethylene, fiberglass, or polypropylene.

For this type of product, the most important factors when choosing are density and transparency. Ideally, the density should be in the range of 120–200 g/m². The higher the film's quality, the higher its cost. However, this is not a case of saving money, as frequent replacement of the covering material will result in significantly higher costs. A greenhouse made of reinforced film will require repairs much less frequently.

Advantages and disadvantages of the material

Reinforced film has the following advantages:

- service life is 3-8 years;

- high strength;

- good tear resistance;

- ability to withstand heavy loads;

- Damaged areas can be easily patched;

- protection of plantings from ultraviolet rays;

- easy installation;

- affordable price.

The main disadvantage of such a product is its strength, which is lower than that of polycarbonate or glass.

As we can see, a reinforced greenhouse cover offers more than just advantages. This is something to keep in mind when choosing this material for finishing this type of structure.