How to insulate a well for the winter yourself

Content

The need for insulation

Insulation plays a crucial role, as inadequate insulation during the cold season reduces the efficiency of all equipment and compromises the system's reliability, which can lead to breakdowns. Water pipes should be insulated from their entry point into the building to a certain depth, which is 35 cm below the point where the ground typically freezes. The pipe should be insulated if the water supply system passes through an uninsulated basement foundation.

For regions where temperatures rarely drop below 15°C, leaves, sawdust, peat, straw, and expanded clay are suitable insulating materials. Climates with harsher winters and critically low temperatures require reliable artificial materials such as mineral wool, foam, expanded polystyrene, and others.

To insulate the system, the riser is usually covered with a metal mesh, a metal casing is placed on top, the selected insulation is poured into the remaining space, and a tin tray is placed under the valve.

Video: Installing a Caisson for a Well

This video will show you how to install a caisson yourself.

Methods of protection

The choice of insulation for utility lines located in the yard is based on parameters such as hygroscopicity, high strength and resistance to deformation and mechanical damage, ease of installation (allowing DIY installation), and practicality and durability. The key elements of preparing a water supply system for winter at your own dacha include insulating the duct and caisson.

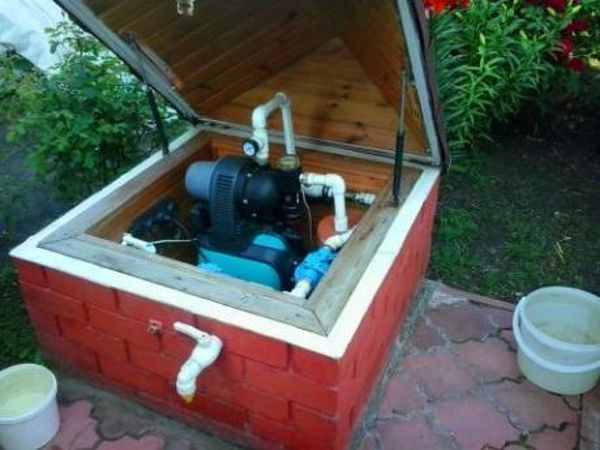

Box

Installing caissons is optional if you live in a mild climate, as the head and equipment are simply placed in an insulated box. This protective structure is constructed of wood or brick during the warmer months and can then be opened as needed. The inside walls of the box must be covered with thermal insulation. The box can act as a small decorative structure, reliably protecting the equipment and piping from the cold.

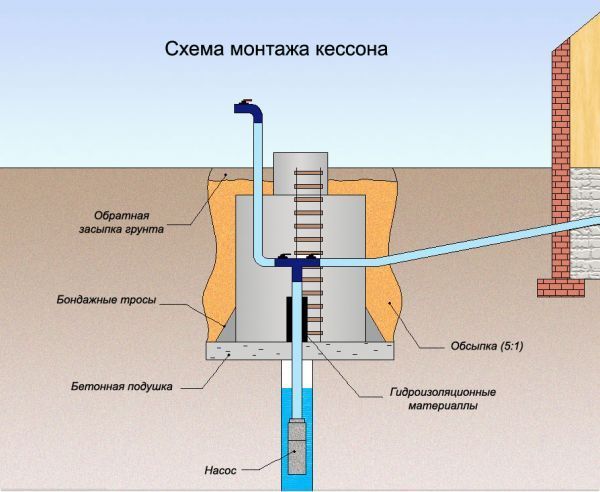

Caisson

The special sealed tank has inlet openings for the inspection hatch and pipe access. Caissons can be cylindrical or rectangular, and materials such as plastic, brick, concrete, and metal are used for their production.

Using insulation to protect the crane along with the rest of the equipment is a common method for insulating hydraulic installations, used in areas with high groundwater levels. Plastic caissons are often used today, installed at a depth of 2–3 meters in a pit with a layer of crushed stone and sand approximately 15 cm high.

It's important to use medium-sized crushed stone rather than fine-grained crushed stone. Bottom perforation is necessary—this is the procedure for the wellhead and sidewall. You'll need to install a special tank, a pipe of the appropriate diameter, and a pumping system. You'll also need to install the material yourself, which is approximately 5 cm thick.

Foam plastic or mineral wool, known for their excellent thermal insulation, are commonly used. To completely prevent ice from forming in the pipes, an additional cover with its own thermal insulation is installed in the summer; the cover should not be opened during cold weather.

Sometimes gardeners install a heating element inside the caissons, equipped with a temperature sensor for convenience. If the space is small, a heating cable about 5 cm long or a lamp with a power of up to 60 watts can serve this purpose.

Caissons are not included in all projects; sometimes, instead, a casing pipe is installed for the head, the diameter of which must be greater than the diameter of the casing by two thicknesses of the thermal insulation material used.

Thermal insulation materials

The pipeline is a vulnerable element of the water supply system, as most of it is located outdoors, albeit hidden underground. Below, we'll explain in detail how to properly insulate a faucet in your yard for the winter using a special heating cable, as well as how to ensure reliable winter protection for both above-ground and underground pipes.

An unconventional method

Preparing a well for winter involves using modern technology. A heating cable serves as insulation. It is reliably protected from possible mechanical damage and, if installed correctly, will last for many years.

Installation is simple and doesn't require any special skills. A pit is dug. The heating element is installed around the circumference of the casing and supply pipe. Low-power models use coils with a small pitch, while higher-power models require a straight line. Mineral wool or fiberglass insulation is used for thermal insulation, as they can withstand the maximum heat generated by the cable when electricity passes through its surface.

The structure is protected from moisture by installing a waterproofing layer on top of this layer. The pit is filled with soil, and the layer is compacted. You can further protect the top of the structure by building a small wooden structure, which will also serve as a decorative element in the garden.

Pipe protection

Preparing a water supply station for the upcoming winter also involves insulating the pipes.

Few summer residents use the "pipe-in-pipe" method, which involves installing an externally insulated pipe, larger in diameter than the existing main pipe, on top of the system. Extending the external pipe into the basement provides a decent supplemental heating source.

Sometimes a second pipe is installed, leading from the basement to the faucets and other equipment. This option is convenient if the owners rarely visit their country house, since the pump can be turned on only when needed, feeding naturally heated groundwater into the pipe.

A popular method for protecting underground pipes from winter frost is to fill the trench with expanded clay during the construction of the plumbing system. For installing underground lines above the frost line, manufacturers recommend polystyrene foam "shells" with a foil-faced protective layer or polyurethane foam. Mineral wool, produced with a special outer waterproofing layer, is also popular.

The following modern materials can provide protection for the water supply system:

- glass wool or mineral wool, which are compressed under the pressure of the earth, which also requires the creation of a special casing;

- basalt fiber with a coating made of aluminum foil - this material is easy to install, but expensive;

- polyurethane foam, which has good thermal insulation qualities and the ability to repel moisture;

- Polystyrene foam and foam plastic are fairly easy to cut and install and provide reliable protection from the cold, but their use requires the creation of protection against rodents.

Shaped shells are used for junctions and turns. Sprayed polyurethane foam is also used as insulation for water lines. When using it, the pipe is placed on a bed of expanded clay, as the bottom of the pipeline is not always covered with a layer of insulation and may be vulnerable to cold.

Thermal paint is a liquid thermal insulator, ideal for hard-to-reach areas where bulk insulation is not suitable. The surface is coated with paint using a spray method or manually with a brush or roller. This material not only provides thermal insulation but also protects metal pipes susceptible to corrosion.

Preparing a private home's autonomous water supply system for winter is easy, as properly designed protection will ensure its uninterrupted operation even in low temperatures.

It is necessary to use insulation for protection in the summer, because even in early autumn there can be severe frosts that can lead to damage to pipes.